Poly Prepartion Dosing System

Poly Preparation Dosing System

Automated Polymer Preparation & Dosing Solution by Avalon Separation

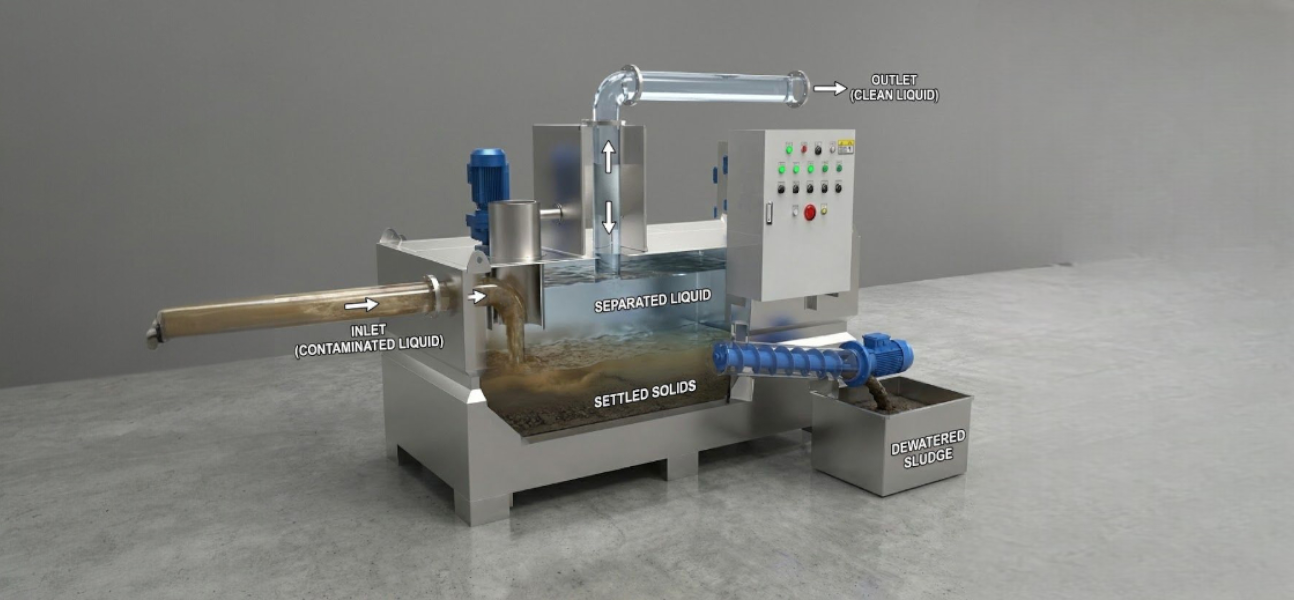

The Poly Preparation Dosing System from Avalon Separation is a compact, fully automated unit designed for precise preparation, maturation, and dosing of liquid or powder polymers. The system ensures uniform flocculant concentration while minimizing footprint, making it ideal for modern water and wastewater treatment facilities.

Also known as polymer dosing systems, powder dosing systems, or PAM / PAC dosing systems, this solution delivers reliable and consistent polymer preparation with minimal operator intervention.

System Design & Working Principle

The Poly Preparation Dosing System is supplied as a pre-assembled modular unit consisting of two cylindrical chambers used for polymer dosing, maturation, and storage. These chambers are hydraulically connected through overflow channels to maintain steady polymer concentration.

Automated dry powder or liquid polymer feeding

Automated dry powder or liquid polymer feeding  Controlled dilution and maturation process

Controlled dilution and maturation process Motor-driven agitators for homogeneous mixing

Motor-driven agitators for homogeneous mixing Compact layout for easy installation

Compact layout for easy installation

The optimized internal flow ensures that the polymer completes its maturation process effectively before dosing.

How the Poly Preparation Dosing System Works

The system prepares ready-to-use polymer solution for effective flocculation and solids separation in water and wastewater treatment processes.

Polymer circulates through multiple compartments using internal baffles

Polymer circulates through multiple compartments using internal baffles This guarantees optimal reaction time and consistent concentration

This guarantees optimal reaction time and consistent concentration Prevents short-circuiting between preparation and dosing zones

Prevents short-circuiting between preparation and dosing zones

Automation is controlled via an electrical control panel connected to an ultrasonic level sensor. When the solution level reaches the low set point, the system automatically starts water intake and polymer feeding. Once the high level is achieved, the preparation cycle stops automatically.

Key Features & Benefits

Fully automated operation

reduces labor and dosing errors

Consistent polymer quality

uniform concentration and maturation

High-efficiency mixer

gentle mixing without polymer degradation

Optimized process control

visual monitoring, alarms, and level control

Compact and modular design

easy transport and relocation

Safe and reliable operation

overflow protection and controlled dosing

Applications

The Poly Preparation Dosing System by Avalon Separation is widely used in:

Aerobic Digestion in Wastewater Treatment

Difference Between Wastewater and Sewage

Disposal Waste Water

Effect of Over Aeration of Activated Sludge

Municipal Wastewater Treatment

Sewage Sludge Overview

Types of Wastewater Treatment Plants

What is Anaerobic Wastewater Treatment

What is BOD in Wastewater

What is Effluent Discharge

What is Municipal Water Supply

What is Raw Sewage

Why Choose Avalon Separation?

Expertise in separation and dosing technologies

Expertise in separation and dosing technologies High-quality, durable system components

High-quality, durable system components Customizable configurations based on process needs

Customizable configurations based on process needs Reliable automation and easy operation

Reliable automation and easy operation Technical support for selection and commissioning

Technical support for selection and commissioning