Avalon Screw Dehydrator

Avalon Screw Dehydrator

Advanced Sludge Dewatering Technology by Avalon Separation

The Avalon Screw Dehydrator (ASD) is a next-generation sludge dewatering solution designed to deliver high efficiency, low operational cost, and reliable performance across industrial and municipal wastewater treatment applications.

Developed with advanced engineering and smart automation, the Avalon Screw Dehydrator eliminates common challenges faced in traditional dewatering systems such as clogging, excessive power consumption, high maintenance, and operator dependency.

What is the Avalon Screw Dehydrator?

The Avalon Screw Dehydrator is a fully enclosed, continuous sludge dewatering system that utilizes a slow-speed screw shaft combined with moving and fixed rings to achieve effective solid-liquid separation.

Unlike belt presses, centrifuges, or filter presses, this technology:

Operates at very low RPM

Operates at very low RPM Consumes minimal water and electricity

Consumes minimal water and electricity Requires minimal supervision

Requires minimal supervision Offers clog-free operation

Offers clog-free operation

The system gradually increases pressure along the screw shaft, producing high dry solid content with minimal odor and noise.

Advantages

Low Power Consumption

Low Power Consumption Reduction of investment costs for thickening and storage equipment

Reduction of investment costs for thickening and storage equipment Widely Use

Widely Use Fully Automatic Control

Fully Automatic Control Contactless, Wear Free Structure Design

Contactless, Wear Free Structure Design High Resistance to Oily Sludge

High Resistance to Oily Sludge No skill Worker Required

No skill Worker Required No Fresh Water Cleaning Required

No Fresh Water Cleaning Required No fresh water cleaning required

No fresh water cleaning required Low Maintenance Required

Low Maintenance Required Clog-free

Clog-free Save Running Cost

Save Running Cost Decrease Capital Investment

Decrease Capital Investment Small Footprint

Small Footprint

Why Avalon Screw Dehydrator is Superior

Clog-Free Self-Cleaning Design

The moving and fixed ring structure continuously self-cleans during operation, eliminating blockages and reducing downtime.

Ultra-Low Energy Consumption

Operating at only 2–4 RPM, the system consumes up to 90% less energy than centrifuges and significantly less than belt presses.

No Fresh Water Requirement

Unlike conventional systems, ASD does not require continuous washing water, drastically reducing water consumption.

Compact & Space-Saving Design

Ideal for retrofitting existing plants or installations with space constraints.

Fully Automatic Operation

PLC-controlled automation enables:

One-touch start & stop

One-touch start & stop Unmanned 24/7 operation

Unmanned 24/7 operation Remote monitoring via SCADA integration

Remote monitoring via SCADA integration

Handles Oily & Fibrous Sludge

Perfect for sludge with high oil, grease, and fiber content.

Key Benefits of Avalon Screw Dehydrator

Low power consumption

Low power consumption Reduced capital investment

Reduced capital investment Minimal maintenance requirement

Minimal maintenance requirement High resistance to oily and sticky sludge

High resistance to oily and sticky sludge No skilled operator required

No skilled operator required Odor-free operation

Odor-free operation Noise-free working environment

Noise-free working environment Long operational life

Long operational life Environmentally friendly process

Environmentally friendly process

Automation & System Integration

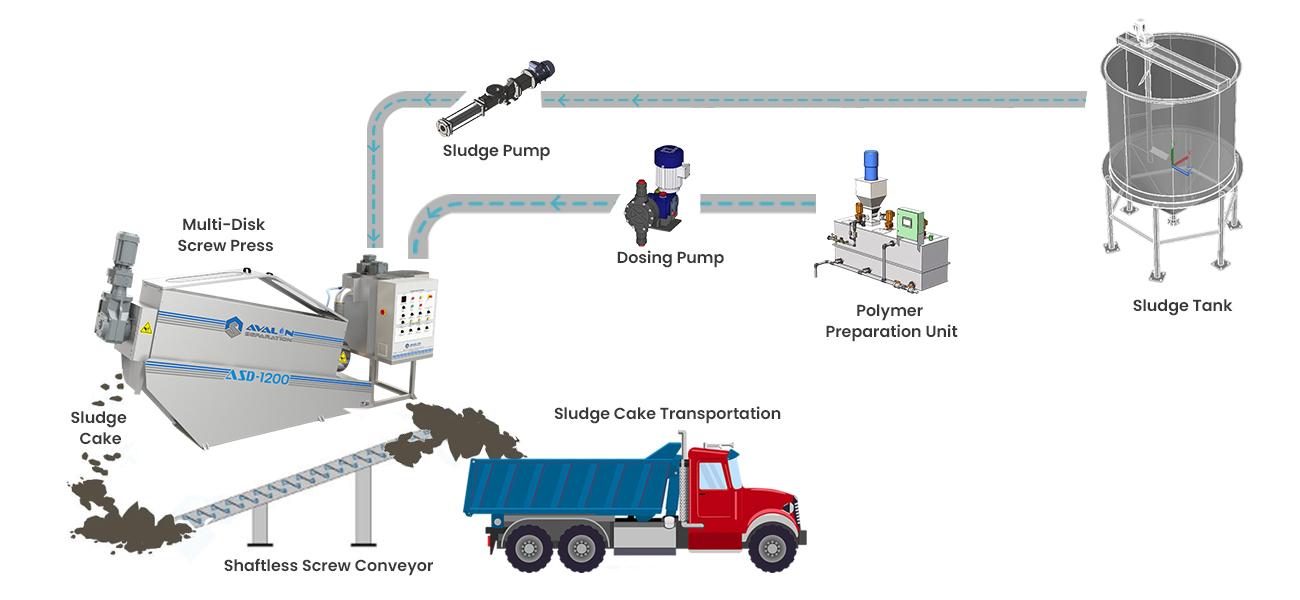

The Avalon Screw Dehydrator is designed for complete process automation and can be easily integrated with:

Polymer dosing systems

Polymer dosing systems Sludge feed pumps

Sludge feed pumps DAF systems

DAF systems Conveyors

Conveyors Central PLC & SCADA

Central PLC & SCADA

The system supports:

Automatic startup & shutdown

Automatic startup & shutdown Alarm management

Alarm management Emergency interruption

Emergency interruption Remote monitoring

Remote monitoring

This ensures maximum safety, reliability, and process optimization.

Direct Dewatering from Oxidation Ditch

Traditional sludge treatment requires pre-thickening before dewatering.

The Avalon Screw Dehydrator eliminates this requirement.

Thanks to its advanced filtration structure, it can process sludge with as low as 0.4% solids concentration, enabling direct dewatering from oxidation ditches without additional thickening tanks.

This results in:

Reduced infrastructure cost

Reduced infrastructure cost Smaller plant footprint

Smaller plant footprint Lower energy consumption

Lower energy consumption

Clog-Free & Odor-Free Operation

The rotating screw shaft causes continuous separation between moving and fixed rings, preventing clogging.

This also ensures:

No accumulation of solids

No accumulation of solids No secondary pollution

No secondary pollution No unpleasant odors

No unpleasant odors

Ideal for indoor installations and urban environments.

Energy-Efficient Performance

The Avalon Screw Dehydrator operates with:

Power consumption as low as 0.01–0.1 kWh/kg-DS

Power consumption as low as 0.01–0.1 kWh/kg-DS Up to 20× lower energy usage than centrifuges

Up to 20× lower energy usage than centrifuges Up to 8× lower than belt presses

Up to 8× lower than belt presses

This significantly reduces operational expenses and carbon footprint.

Compact Design – Small Footprint

The compact footprint allows installation in areas where traditional systems cannot fit.

It is ideal for:

Retrofit projects

Retrofit projects Space-restricted plants

Space-restricted plants Mobile treatment systems

Mobile treatment systems

Ideal for indoor installations and urban environments.

Technical Specifications (Indicative)

Throughput depends on sludge characteristics and operating conditions.

| Model | 1% TS (m³/h) | 2% TS (m³/h) | 3% TS (m³/h) | Cylinder | Power (kW) |

|---|---|---|---|---|---|

| ASD-1100 | 0.5 | 0.3 | 0.2 | 100×1 | 0.24 |

| ASD-1150 | 1.0 | 0.6 | 0.4 | 150×1 | 0.37 |

| ASD-1200 | 3.0 | 1.8 | 1.3 | 200×1 | 0.49 |

| ASD-2200 | 6.0 | 3.5 | 2.6 | 200×2 | 0.86 |

| ASD-1300 | 5.0 | 3.0 | 2.1 | 300×1 | 1.0 |

| ASD-2300 | 10 | 6.0 | 4.2 | 300×2 | 2.0 |

| ASD-1400 | 10 | 6.0 | 4.2 | 400×1 | 1.47 |

| ASD-2400 | 20 | 12 | 8.5 | 400×2 | 2.57 |

| ASD-3400 | 30 | 18 | 13 | 400×3 | 3.67 |

| ASD-4400 | 40 | 24 | 16 | 400×4 | 5.14 |

| ASD-1450 | 15 | 9 | 6.5 | 450×1 | 1.87 |

| ASD-2450 | 30 | 18 | 13 | 450×2 | 3.37 |

| ASD-3450 | 45 | 27 | 20 | 450×3 | 5.24 |

| ASD-4450 | 60 | 36 | 25 | 450×4 | 6.74 |

⚠️ Specifications may vary based on sludge composition and site conditions. Please consult Avalon Separation for final model selection.

Applications

The Avalon Screw Dehydrator is widely used across multiple industries:

chemical processing plants

dairy & meat processing industries

food & beverage processing units

industrial effluent treatment plants

municipal wastewater treatment plants

oil , gas & refinery sludge treatment

sludge from biological treatment processes

textile & dyeing industries

Why Choose Avalon Separation?

Over 9+ years of industry expertise

Over 9+ years of industry expertise 130+ successful installations worldwide

130+ successful installations worldwide Proven reliability in harsh environments

Proven reliability in harsh environments Custom-built solutions for every application

Custom-built solutions for every application Strong after-sales service & technical support

Strong after-sales service & technical support Sustainable, eco-friendly engineering approach

Sustainable, eco-friendly engineering approach